Englover

The problem with gloves

During the last semester of my

M. Eng program, I had the opportunity to engage in the design process to solve this seemingly straightforward problem. The scope of work for the project

was to prototype a working model given the design challenge and to create a plan for large scale production. All related IP is owned by Englover.

During the last semester of my

M. Eng program, I had the opportunity to engage in the design process to solve this seemingly straightforward problem. The scope of work for the project

was to prototype a working model given the design challenge and to create a plan for large scale production. All related IP is owned by Englover.

Scope of Work

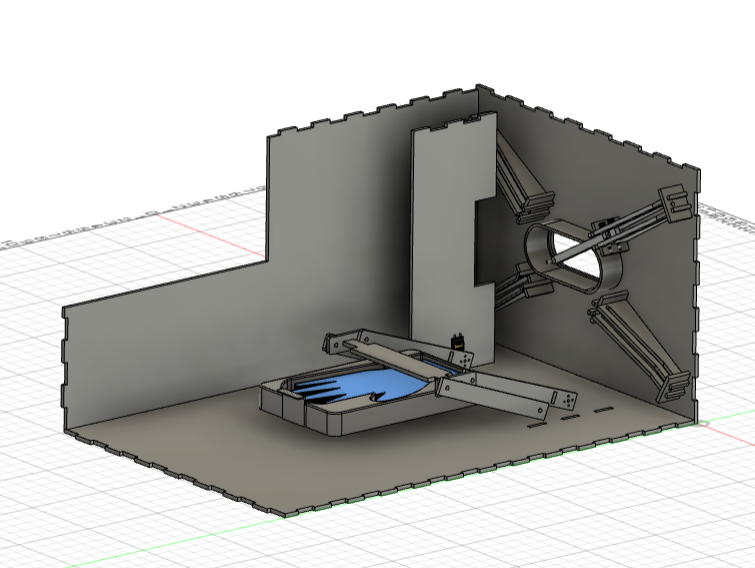

My work for Englover consisted

primarily of making CAD, often preceded by 2D hand sketches, and physically cutting/printing pieces and putting them together. I used Autodesk Fusion 360

for CAD and university facilities for laser cutting and 3D printing. I programmed the actuators using Arduino and for the scope of the project, controlled

them using my laptop. On a high level, the machine works by creating a sealed box (finger jointed acrylic plates) where the glove comprises some portion of the outer surface area. A vacuum

pump is then activated, creating a negative pressure difference that inflates the glove inwards and makes the donning process easy and fast.

The machine worked in 3 stages:

My work for Englover consisted

primarily of making CAD, often preceded by 2D hand sketches, and physically cutting/printing pieces and putting them together. I used Autodesk Fusion 360

for CAD and university facilities for laser cutting and 3D printing. I programmed the actuators using Arduino and for the scope of the project, controlled

them using my laptop. On a high level, the machine works by creating a sealed box (finger jointed acrylic plates) where the glove comprises some portion of the outer surface area. A vacuum

pump is then activated, creating a negative pressure difference that inflates the glove inwards and makes the donning process easy and fast.

The machine worked in 3 stages:

- Pickup

- Expansion

- Evacuation

Pickup

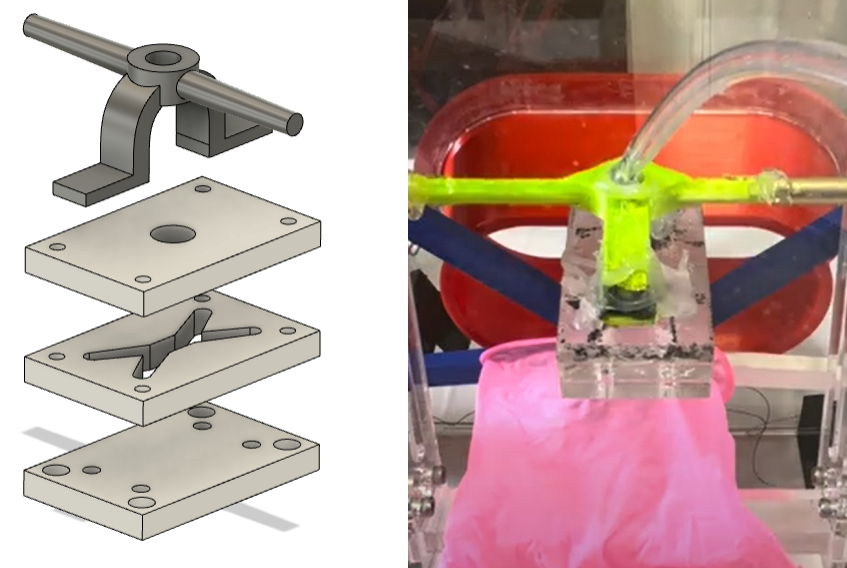

The first step of the machine involves picking up the glove from a stack and moving it up and across to 'present' it to a slot shaped bill. There are

2 components to the pickup: the 'sticking' component and the actuating component. Since the effector needs to go through many binary cycles of attaching/de-attaching

from the glove, a suction plate made the most sense. The component is made of 3 laser cut acrylic plates that create a channel from an input tube to split into

4 suction points. Though the pickup success rate was fairly high after some iterations, there was a margin of error of +/- 0.75" of the glove's mouth after lifting

the glove due to the flimsiness of the glove material. This meant the expansion mechanism had to be able to account for different geometries of the glove mouth, i.e.

accept a 'noisy' input.

The first step of the machine involves picking up the glove from a stack and moving it up and across to 'present' it to a slot shaped bill. There are

2 components to the pickup: the 'sticking' component and the actuating component. Since the effector needs to go through many binary cycles of attaching/de-attaching

from the glove, a suction plate made the most sense. The component is made of 3 laser cut acrylic plates that create a channel from an input tube to split into

4 suction points. Though the pickup success rate was fairly high after some iterations, there was a margin of error of +/- 0.75" of the glove's mouth after lifting

the glove due to the flimsiness of the glove material. This meant the expansion mechanism had to be able to account for different geometries of the glove mouth, i.e.

accept a 'noisy' input.

The actuating component needs to be position-controlled, fairly low-torque, and only 1 independant DOF. Thus a singular servo should be able to do the job. The servo

and apparatus need to be secure relative to the box so they were mounted on two parallel plates that spanned the height of the box. The pickup mechanism traveled in

between the plates for stability and the servo lay outside to take up less space. I considered 2 designs for the pickup apparatus: a simple 4 bar linkage with fairly

fixed ranges of motion, and a more adaptable 2-slot design where the axle rotates + travels (pinslots) in one and a corresponding 'angle control' key travels the other.

While the linkage is simpler, the second option allows us more flexibility in the path and more specifically the angle of incidence when the glove is presented to the

extractors.

The actuating component needs to be position-controlled, fairly low-torque, and only 1 independant DOF. Thus a singular servo should be able to do the job. The servo

and apparatus need to be secure relative to the box so they were mounted on two parallel plates that spanned the height of the box. The pickup mechanism traveled in

between the plates for stability and the servo lay outside to take up less space. I considered 2 designs for the pickup apparatus: a simple 4 bar linkage with fairly

fixed ranges of motion, and a more adaptable 2-slot design where the axle rotates + travels (pinslots) in one and a corresponding 'angle control' key travels the other.

While the linkage is simpler, the second option allows us more flexibility in the path and more specifically the angle of incidence when the glove is presented to the

extractors.

Expansion

The expansion mechanism takes the loose glove presented by the pickup mechanism, stretches, and then deposits the glove around a slot shaped bill,

completing the seal for the box. The mechanism needs high torque (gloves are quite resistive), multiple contact points with the glove, at least 4 total DOF,

actuation in both directions, compact (fitting inside the box without making the box ridiculously big). I dismissed any ideas that required more than 1

motor primarily because it'd be inefficient and I enjoy 'doing more with less''. Though,

it also fit nicely with the other constraints. I designed a pulley system in which 1 central motor rotated a pulley which had strings

connected to 4 sets of finger. The fingers used 2 screws as pins to travel through a slot in the extractor that gently

transitioned from pulling the glove out to down. This allowed me to achieve 8 different axes of motion using one motor. A rubber 'dental dam'

was later replaced by a rubber band for a passive return mechanism.

The expansion mechanism takes the loose glove presented by the pickup mechanism, stretches, and then deposits the glove around a slot shaped bill,

completing the seal for the box. The mechanism needs high torque (gloves are quite resistive), multiple contact points with the glove, at least 4 total DOF,

actuation in both directions, compact (fitting inside the box without making the box ridiculously big). I dismissed any ideas that required more than 1

motor primarily because it'd be inefficient and I enjoy 'doing more with less''. Though,

it also fit nicely with the other constraints. I designed a pulley system in which 1 central motor rotated a pulley which had strings

connected to 4 sets of finger. The fingers used 2 screws as pins to travel through a slot in the extractor that gently

transitioned from pulling the glove out to down. This allowed me to achieve 8 different axes of motion using one motor. A rubber 'dental dam'

was later replaced by a rubber band for a passive return mechanism.

Evacuation

The evacuation depends highly on the permeability of the box. As a prototype, finger jointed acrylic plates are convenient but are not

very airtight. With electrical tape, the problem was significantly mitigated but at scale the solution would certainly be a different box

manufacturing method that allows it to be 2 pieces - something like vacuum formed composites with a hinge and rubber t - rather than 6+. Note

in the video that the glove inflates inwards first (due to the pressure differential) and that makes it much easier to insert a hand. Ultimately,

the scaled version will have to include hardware that allows the openings of the box to be reliably opened and closed (for replacing glove supply,

maintainence, etc.), maintaining a seal after many cycles. Today, I'm still working on microadjustments for the existing design and different ways

to execute various subcomponents. Its been a great learning so far and I'm looking forward to updating this page when its done.

The evacuation depends highly on the permeability of the box. As a prototype, finger jointed acrylic plates are convenient but are not

very airtight. With electrical tape, the problem was significantly mitigated but at scale the solution would certainly be a different box

manufacturing method that allows it to be 2 pieces - something like vacuum formed composites with a hinge and rubber t - rather than 6+. Note

in the video that the glove inflates inwards first (due to the pressure differential) and that makes it much easier to insert a hand. Ultimately,

the scaled version will have to include hardware that allows the openings of the box to be reliably opened and closed (for replacing glove supply,

maintainence, etc.), maintaining a seal after many cycles. Today, I'm still working on microadjustments for the existing design and different ways

to execute various subcomponents. Its been a great learning so far and I'm looking forward to updating this page when its done.